What are UHPC CONC and HPC CONC concretes?

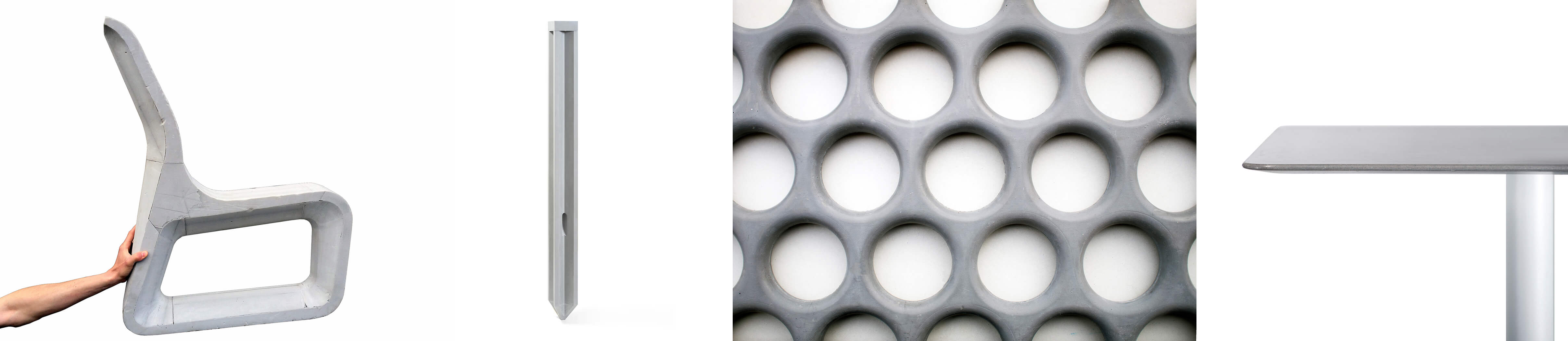

UHPC (ultra-high performance concrete) and HPC (high-pressure concrete) were developed in Europe in the 80s to meet the highest requirements for concrete in architecture, construction and design. The main qualities of the material are high strength, low water absorption, corrosion resistance.

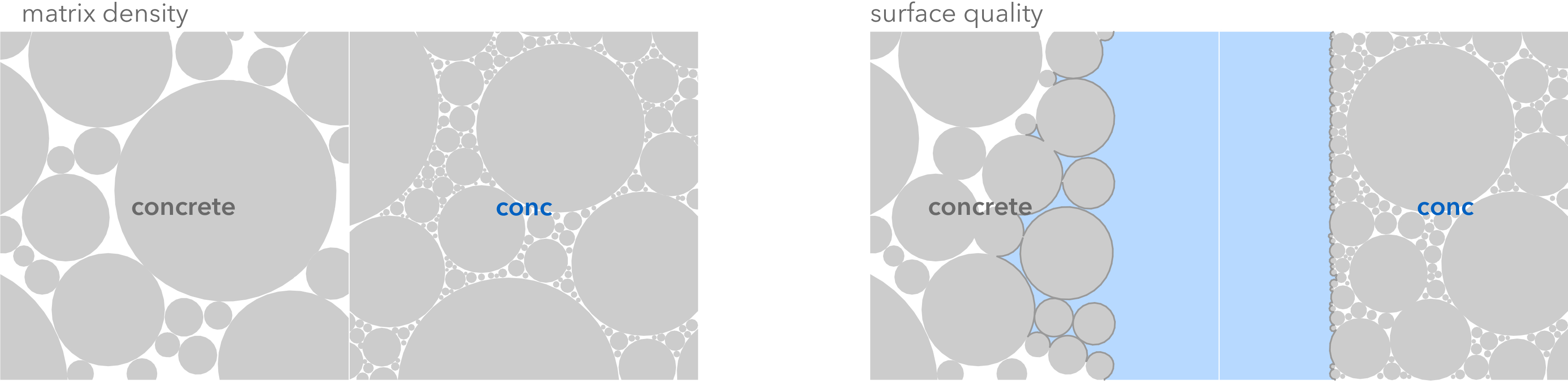

The main advantage of concrete HPC and UHPC over conventional concrete is the high-density structure of the material. This is achieved through the selection of component materials, the use of special additives and a special technology for the preparation of the mixture. Absorption of moisture structure of the material is minimal, which gives high frost resistance and consequently increases the service life of the products.

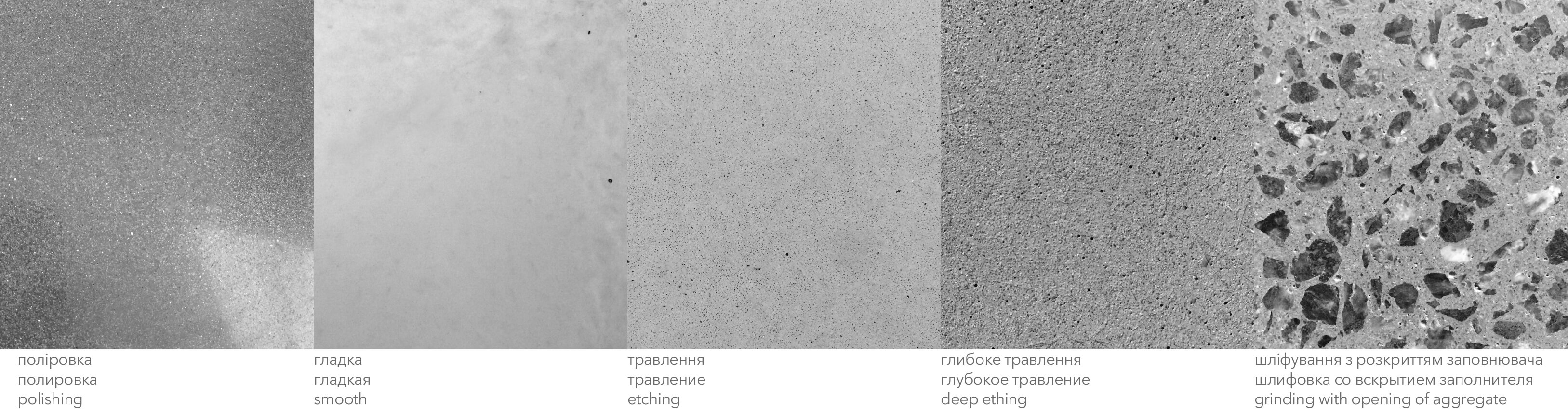

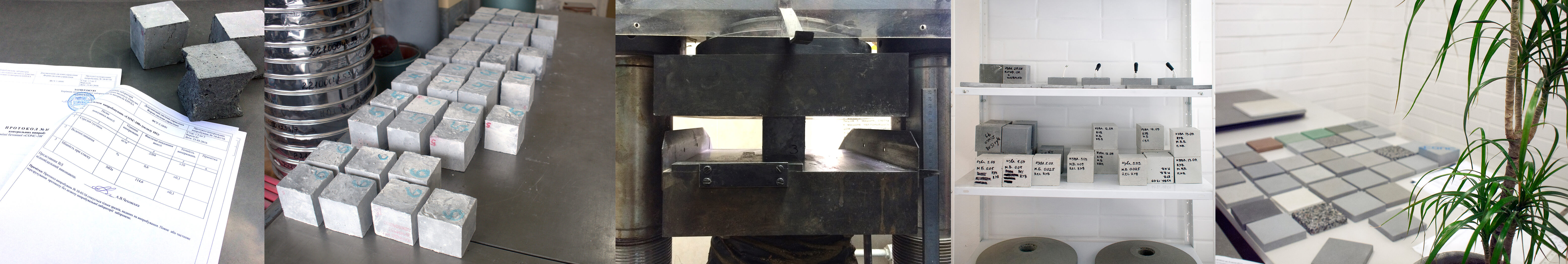

This material consists of natural mineral fillers. We adapted the concrete formulations to Ukrainian components of local origin to avoid excessive transportation costs and, as a result, optimize the cost of the products. The components of the mixture and their dosages are carefully selected for each product, depending on the desired result.